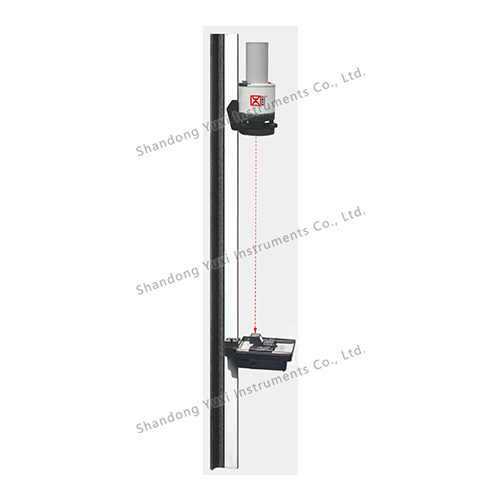

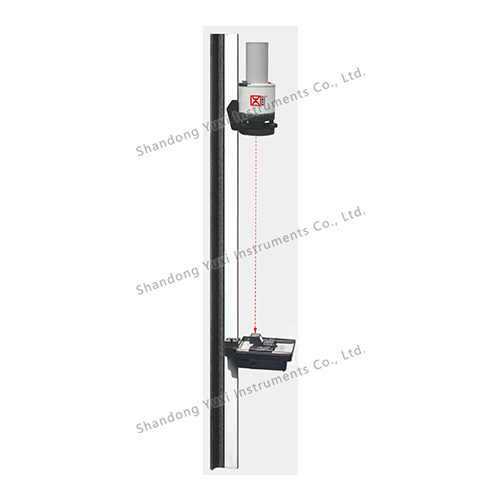

LGV Lift guide rail verticality tester

Description

Description

LGV series lift guide rail verticality tester is mainly used to measure the verticality and straightness of lift guide rails. It is suitable for on-site inspection of lifts in lift installation departments and other units. It is also suitable for online inspection and maintenance of maintenance companies.

Detecting the linear deviation of the two rails of the lift (full process) requires a measurement benchmark. Using the top-down laser beam, after the double wedge liquid compensation, a high-precision plumb reference line is formed. The verticality and linearity of the guide rail are measured with the plumb reference, and the verticality of the left and right rows of guide rails is analyzed , You can get the parallelism deviation of the two rails in space, which is the key technology of the product.It solves the problem that the linear deviation of the guide rail cannot be detected because of the settlement of the building foundation and the shrinkage of the cement on the wall of the guide rail.

It is composed of laser, optical collimation system, automatic compensation system, power supply and circuit system, as well as mechanical parts including special fixtures, adjustment handwheels, round blisters, and shells. It forms a complete lift guide rail measurement system with digital display light targets or other light targets.

Functions

1、In the vertical lift installation, the reference line is placed on the sample frame, instead of the traditional plumb process, which improves the plumb weight accuracy and work efficiency of the line

2、Perform quality inspection on the installed guide rails to ensure smooth and comfortable operation of the car

3、When the running car shakes, check the guide rail to find out the direction and size of the deviation to correct it

4、When the lift is refitted, the original guide rail can be detected and corrected

5、The ring grating light source is used as the vertical reference, and the spatial phase modulator is used to avoid the poor focusing operation

6、The vertical collimator adopts liquid double wedge compensation technology, which improves the stability of measurement

7、The deviation value of the two-dimensional direction coordinate of the guide rail is displayed in digital form, which is easy to read and record

8、Equipped with safety rope to prevent instrument falling and improve safety

Parameters

1、Standard deviation: 1/200000

2、Auto compensation error: 0.048″ (t-20)/1′

3、Laser wavelength: 658 nm

4、Output laser maximum optical power: <1 mW

5、Center spot diameter: At 100m ≤ φ8mm ; At 50m ≤ φ3mm

6、Auto leveling damping time: <15s

7、Operating Temperature: -20 ~ 50 ℃

8、Operating humidity: <90% RH

9、Working distance: 0~100 m

10、Power: DC 3V

11、Working current: ≤ 90 mA

12、Weight: 1.56 kg

13、Dimension: φ142×250 mm

【Digital display target】

1、Range: 60×70 mm

2、Accuracy: 0.02 mm

3、Power: AG 12

4、Weight: 0.96 kg

5、Dimension: 181×162×81 mm